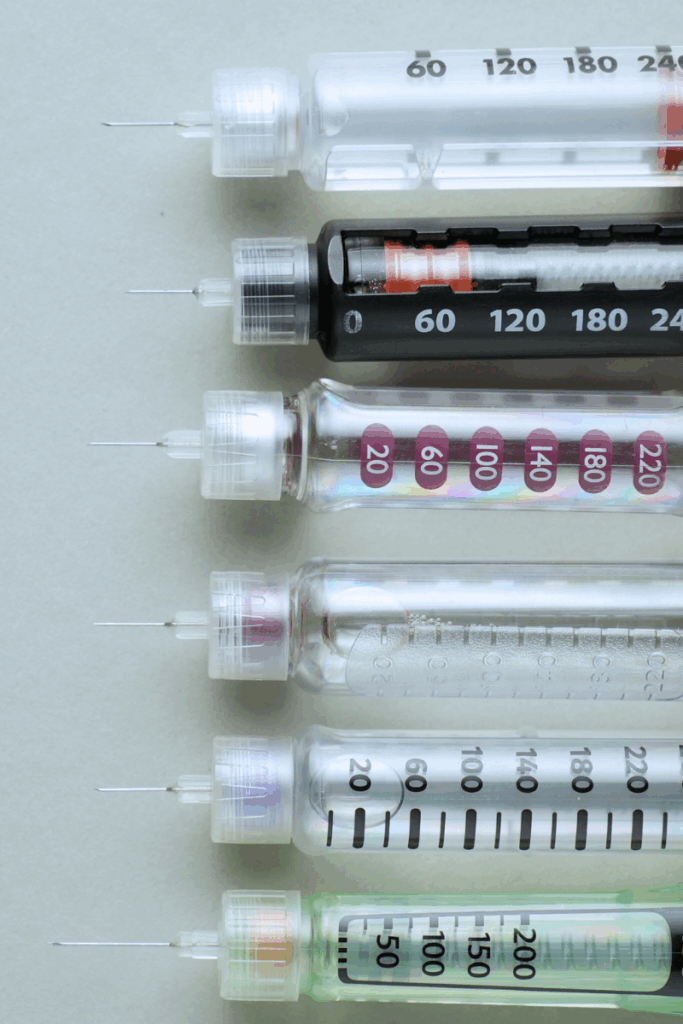

GLP-1 Manufacturers

GLP-1 manufacturers are leading one of the fastest-growing categories in modern healthcare — delivering therapies that demand precision, performance, and speed.

Veritiv can help you meet that challenge with validated cold chain systems designed for consistency, compliance, and sustainability at scale. From testing and validation to fulfillment and optimization, we work alongside your teams to help strengthen performance, reduce complexity, and support continued growth across global markets.

-

Fulfillment

-

Testing

-

Centralized Partner

-

Sustainability

-

Lean Operations

-

Cost Analysis

-

Industry Expertise

Proven Partnership

With decades of experience serving healthcare innovators, Veritiv helps connect proven packaging science with the precision today’s therapies demand.

Designed for a New Standard of Scale

The GLP-1 market is growing fast and Veritiv can help you grow with it. Our scalable, validated packaging systems are developed to support large-volume production with precision and sustainability in mind.

We continue to invest in new materials, smarter validation, and fulfillment strategies that help manufacturers stay ahead of growing demand.

Reach That Delivers

With more than 120 distribution centers and 60 fulfillment sites across North America, Veritiv can help you get validated packaging where it’s needed, when it’s needed.

Our expansive network supports faster access, consistent quality, and reliable service for the therapies patients depend on.

Frequently Asked Questions (FAQs)

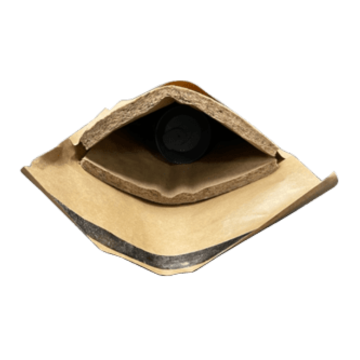

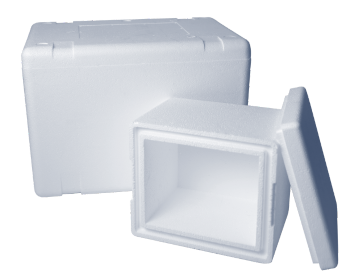

A. Cold Chain refers to the process or products involved in shipping temperature-sensitive items from origin to destination while maintaining a stable environment within the cooler. This prevents spoilage of food and maintains the stability and efficacy of life-altering medications.

A. The four conventional temperature ranges are:

Frozen/Dry Ice (<-20°C) Refrigerated (2-8°C) Ambient/Room Temp (15-25°C) Cryogenic/Liquid Nitrogen Frozen (>-80°C)

A. Temperature excursion occurs when a product that must maintain a specific temperature range falls below or exceeds that range. For example, if a product required to stay between 2°C – 8°C falls below 2°C or rises above 8°C, it results in a temperature excursion.

A. Many factors are used to determine when dry ice should be used over frozen gel packs. Dry ice is one of the more costly options but offers the best duration. It sublimates up to 10 pounds per day depending on the ambient temperature and turns into carbon dioxide. Be cautious of trapped gases when opening the cooler.

Contact Us

Our experts create custom solutions to keep your temperature-controlled products safe and efficient during delivery. Contact us today to get started!