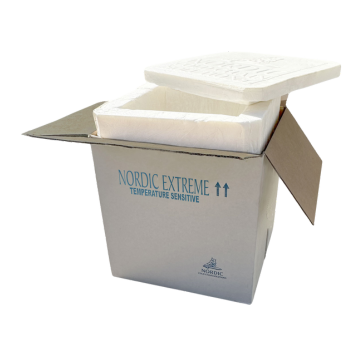

Molded PUR

High-Performance Reliability

Engineered for consistency across frozen, refrigerated, and CRT ranges, molded polyurethane (PUR) can help maintain precise control for up to 120 hours—supporting the most demanding cold chain applications.

Reusable Durability

Designed for multiple-use systems, some molded PUR shippers can help reduce waste and total cost of ownership through their strong, impact-resistant structure. Their durable insulation can enable repeat performance, offering a reusable solution for critical product protection.

Validated Confidence

Available in prequalified configurations and compatible with phase change materials (PCMs), molded PUR systems can help you accelerate deployment while maintaining regulatory compliance. Each solution can help you ship with confidence, even under the most stringent requirements.

Thermal Precision

Engineered for endurance and consistency, molded polyurethane (PUR) systems deliver high-performance insulation that helps safeguard temperature-sensitive products through even the longest, most demanding cold chain routes.

Frequently Asked Questions (FAQs)

A. Cold Chain refers to the process or products involved in shipping temperature-sensitive items from origin to destination while maintaining a stable environment within the cooler. This prevents spoilage of food and maintains the stability and efficacy of life-altering medications.

A. The four conventional temperature ranges are:

Frozen/Dry Ice (<-20°C) Refrigerated (2-8°C) Ambient/Room Temp (15-25°C) Cryogenic/Liquid Nitrogen Frozen (>-80°C)

A. Temperature excursion occurs when a product that must maintain a specific temperature range falls below or exceeds that range. For example, if a product required to stay between 2°C – 8°C falls below 2°C or rises above 8°C, it results in a temperature excursion.

A. Many factors are used to determine when dry ice should be used over frozen gel packs. Dry ice is one of the more costly options but offers the best duration. It sublimates up to 10 pounds per day depending on the ambient temperature and turns into carbon dioxide. Be cautious of trapped gases when opening the cooler.

Contact Us

Our experts create custom solutions to keep your temperature-controlled products safe and efficient during delivery. Contact us today to get started!