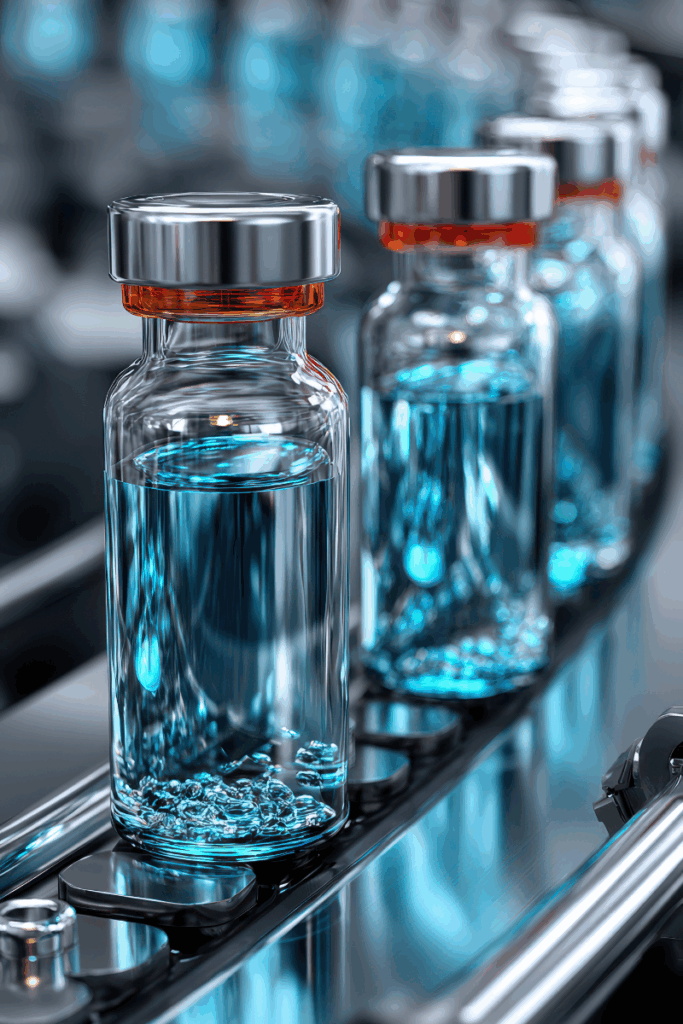

Global Biopharmaceutical

Global biopharma companies are advancing the next generation of therapies and we’re here to help protect them. Veritiv partners with your teams to design, test, and deliver validated cold chain packaging that supports product integrity, compliance, and sustainability. Powered by science and built for scale, we help you move life-changing innovations forward with confidence.

-

Testing

-

Solution Agnostic

-

Global Network

-

Validated

-

Compliance

Compliance -

Sustainability

-

Built to Scale

Preserve & Protect

Built for Collaboration

Global programs succeed when every partner moves in sync. Veritiv brings structure and clarity to complex cold chain initiatives by aligning packaging, logistics, and quality teams around shared data, documentation, and goals.

Through transparent communication and technical collaboration, we help your teams move faster, stay compliant, and bring therapies to patients with greater confidence.

One Partner, Global Consistency

Managing multiple packaging suppliers across regions can slow progress and create costly inconsistencies. Veritiv helps global biopharma companies streamline complexity by acting as a single point of contact for cold chain packaging.

Through centralized coordination and globally validated systems, we can help your teams focus less on managing vendors and more on advancing what matters most: the science at the core of your business.

Frequently Asked Questions (FAQs)

A. Cold Chain refers to the process or products involved in shipping temperature-sensitive items from origin to destination while maintaining a stable environment within the cooler. This prevents spoilage of food and maintains the stability and efficacy of life-altering medications.

A. The four conventional temperature ranges are:

Frozen/Dry Ice (<-20°C) Refrigerated (2-8°C) Ambient/Room Temp (15-25°C) Cryogenic/Liquid Nitrogen Frozen (>-80°C)

A. Temperature excursion occurs when a product that must maintain a specific temperature range falls below or exceeds that range. For example, if a product required to stay between 2°C – 8°C falls below 2°C or rises above 8°C, it results in a temperature excursion.

A. Many factors are used to determine when dry ice should be used over frozen gel packs. Dry ice is one of the more costly options but offers the best duration. It sublimates up to 10 pounds per day depending on the ambient temperature and turns into carbon dioxide. Be cautious of trapped gases when opening the cooler.

Contact Us

Our experts create custom solutions to keep your temperature-controlled products safe and efficient during delivery. Contact us today to get started!